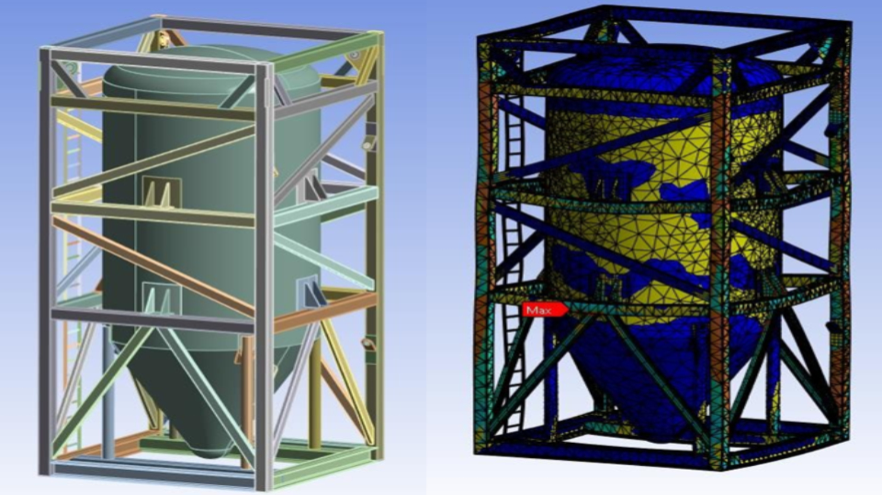

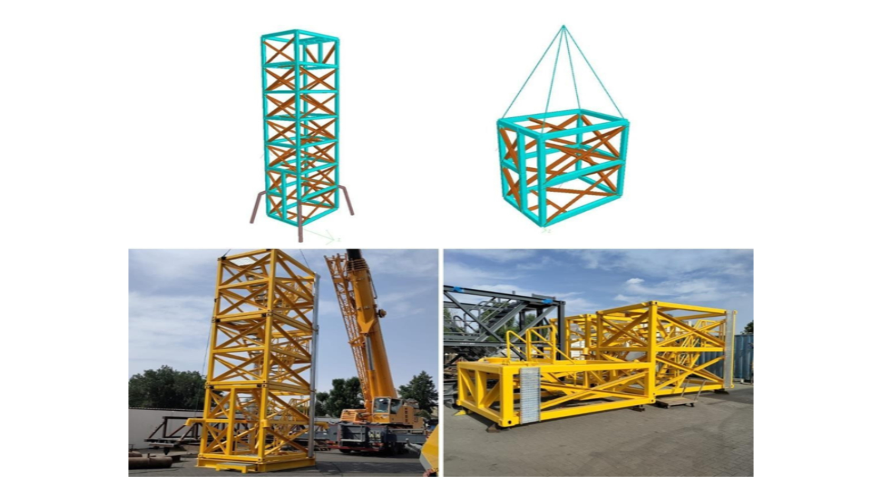

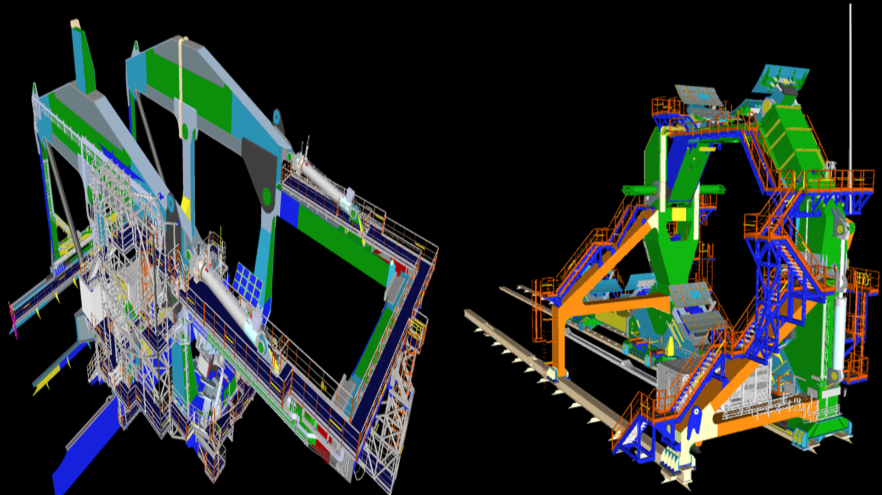

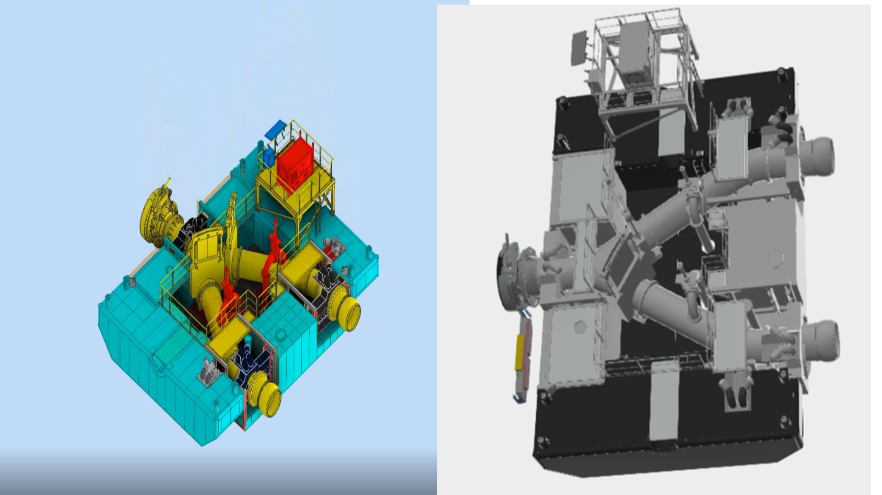

S&O Maritime Services specializes in managing complex marine and offshore engineering projects, delivering tailored solutions with a focus on technical precision, safety, and operational efficiency. Our Special Projects division supports a wide range of customized engineering needs, including: Vessel retrofits and conversions, Offshore structure modifications and reinforcement, Integration of new systems and technologies, Special-purpose vessel upgrades, and Feasibility studies and technical assessments. With a deep understanding of industry regulations and classification requirements, our engineers and project managers ensure seamless coordination from concept development through design, engineering, and final execution.