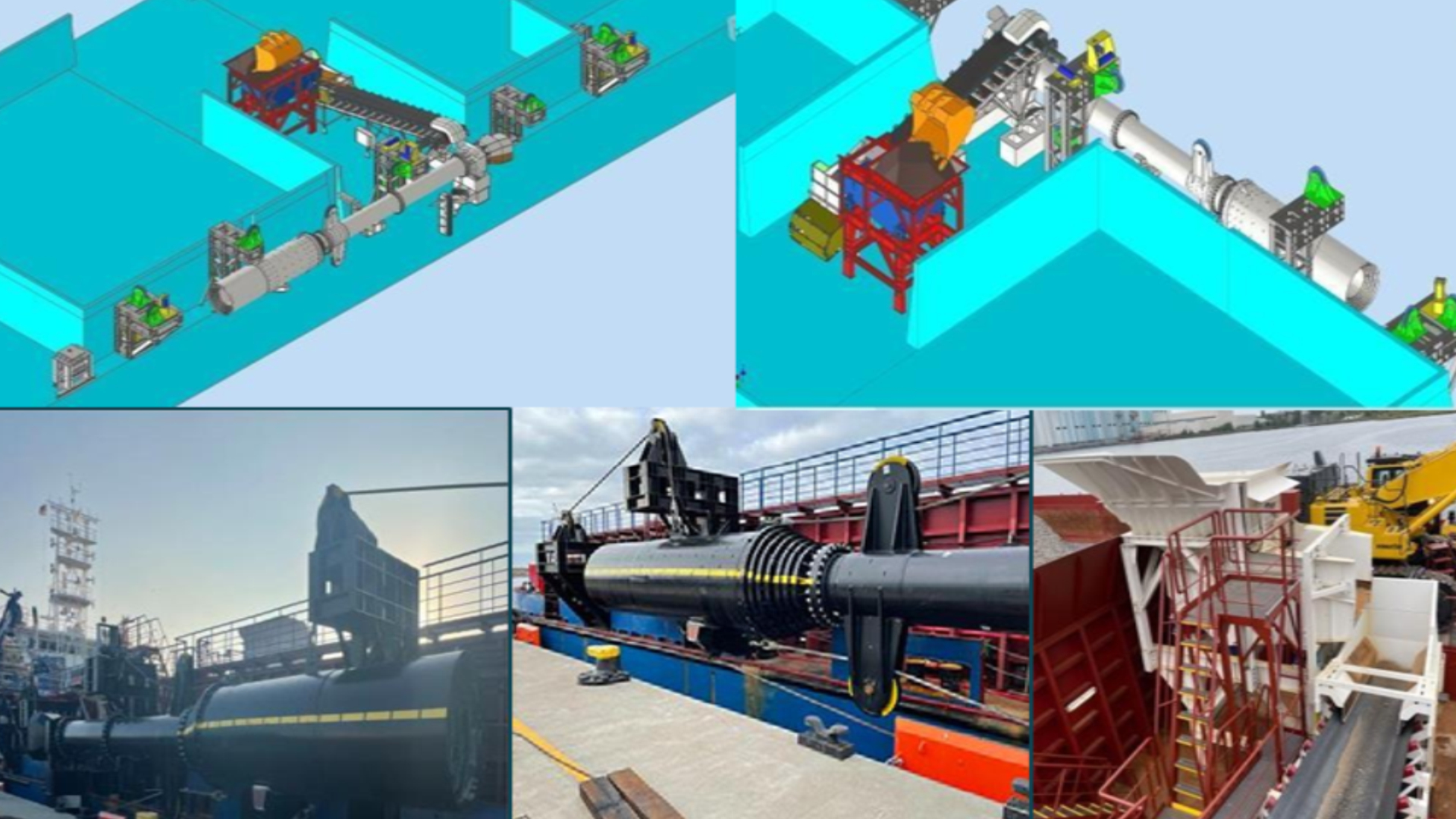

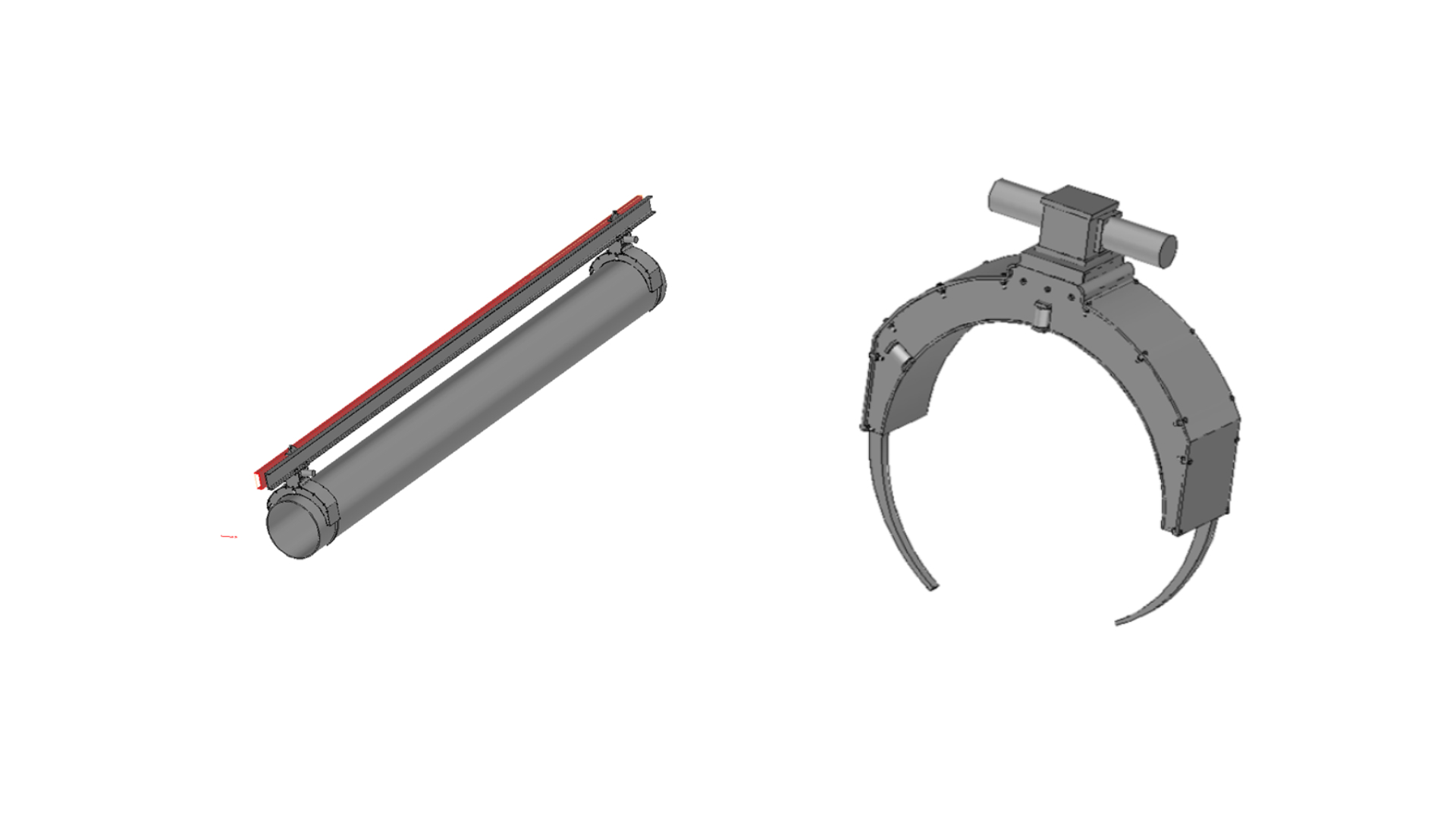

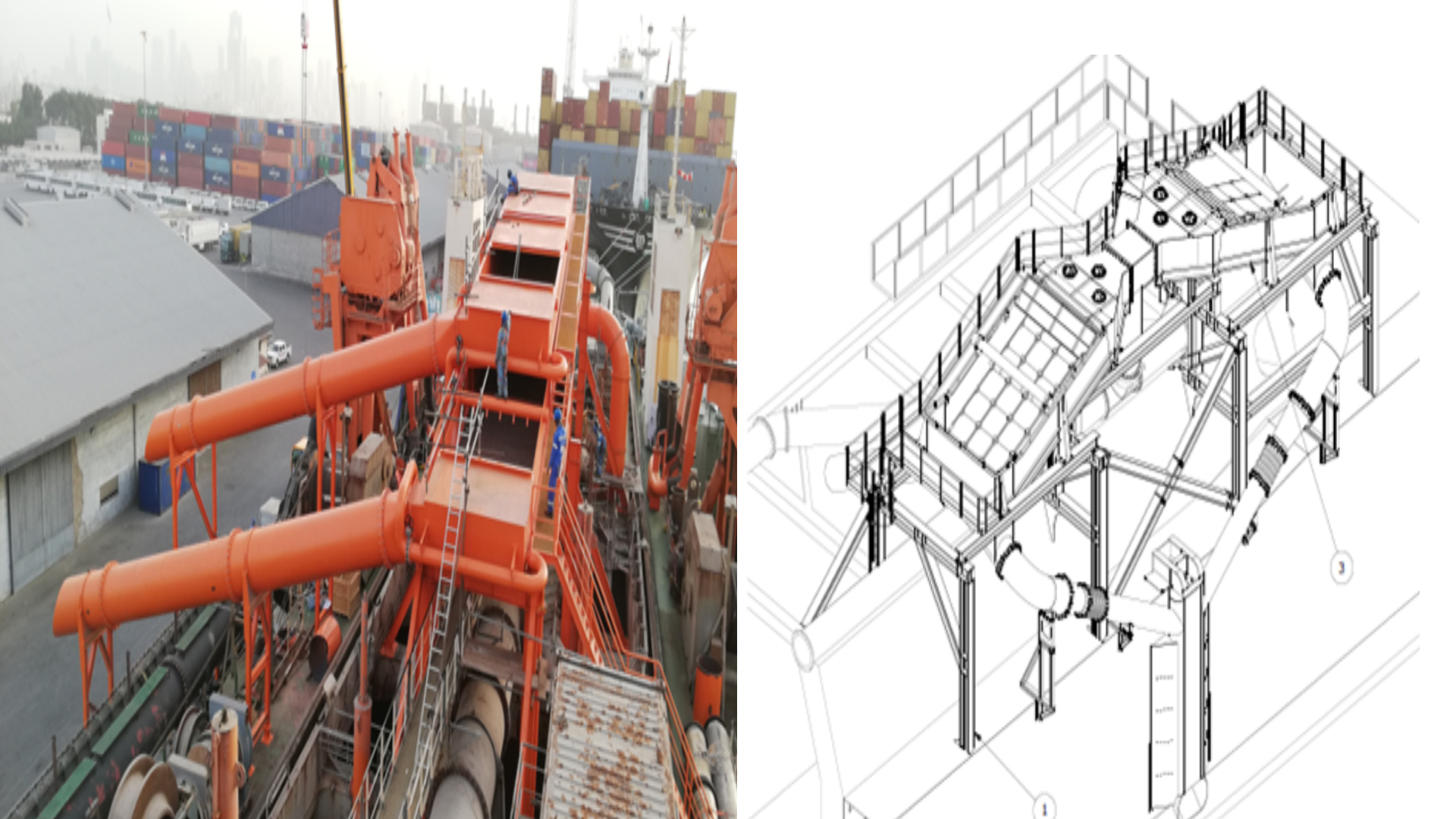

S&O Maritime Services offers end-to-end product design services, turning initial ideas into fully developed marine and offshore engineering solutions. From conceptual sketches to 3D modeling, structural validation, and prototyping support, we ensure each design is practical, innovative, and ready for fabrication. We collaborate closely with clients to understand operational goals and constraints, ensuring that every design is optimized for performance, safety, manufacturability, and compliance with international standards. Whether it’s a new vessel component, offshore equipment, or a custom structural solution, we combine creative vision with engineering expertise to deliver reliable, high-performance results.